A floor jack is perhaps one of the most frequently used pieces of equipment in any garage or workshop. From changing a tire on a car, to repairing brakes on a vehicle, or just inspecting undercarriage components, there is usually the need to use some form of lifting equipment in order to do the job efficiently. These machines play an incredibly important role to the success of a variety of mechanical tasks and if not used with the proper techniques can result in damaging the vehicle and even putting the individual using it at risk. In order to minimize the potential for mistake, it is vital that all safe lifting practices are adhered to.Knowing the most common mistakes made with a floor jack is crucial in order to protect the safety of the vehicle, the safety of the lifting equipment and first and foremost the safety of the user. https://standesign.ca/common-floor-jack-mistakes-that-can-damage-your-vehicle/ READ MORE

Posts

New technologies in modern vehicles are making routine maintenance easier and quicker. Here at Total Garage Tools, we believe the best example of this is the use of an electric jack. While electric jacks are commonly used when changing a tire on the side of the road after a flat has been suffered due to a puncture, they are also used a huge amount in actual garage settings when vehicles are serviced.In this guide, we’ll explain what an electric jack is, how it works, its types, and why it’s becoming a preferred lifting solution. https://standesign.ca/what-is-an-electric-jack-and-how-does-it-work/ READ MORE

Today, the keys to successful high volume automotive repair shops and quick service oil change facilities are speed, quality and safety. An essential tool in a fast lube shop and any high volume repair shop is a fast lube jack. It enables quick access to all four wheels and allows for fast wheel changes while still maintaining a high level of safety for all personnel.In this blog we will delve into the world of fast lube jacks and describe their function, impact and overall purpose. Service centers and repair shops are continually on the lookout for options to streamline and boost the speed and productivity of their operations. Fast lube jacks represent a well-regarded answer to these needs and are currently a popular choice among many shop proprietors. https://standesign.ca/what-are-fast-lube-jacks-and-how-do-they-improve-service-efficiency/ READ MORE

Heavy vehicle lifting is an important aspect of any fleet maintenance operation, truck repair facility or industrial workshop. Heavy duty lifts and truck jacks are just a couple of the pieces of heavy lifting equipment used when a vehicle needs to be lifted and checked for damage or maintenance required. Heavy vehicle lifting is a very dangerous process and any failures caused from inadequately modified or worn heavy lifting equipment, incorrect loading of the vehicle, an unsuitable surface for lifting or even incorrect lifting procedures can result in serious injury and damage to the vehicle and any accompanying persons.Implementing safe operating procedures and risk control measures is crucial to enable all lifts to be carried out in a safe, compliant and efficient manner.Why Risk Management Is Crucial in Heavy Vehicle LiftingObjects these vehicles can weigh anywhere from several tons to over 40 tons. Heavy Objects improper lifting of heavy objects can cause heavy injury. https://standesign.ca/managing-risk-in-heavy-vehicle-lifting-operations/ READ MORE

Change rocks the truck repair world, sparked by tech gains, tougher safety rules, and people wanting faster results. Equipment like electric jacks and hybrid models – blending battery-run systems with old-style fluid-based mechanics – now shape how vehicles get hoisted inside garages or on highways. With smooth motor-driven lifts paired beside familiar pump-run setups, today’s tools redefine what works, boosting speed, cutting risks, and making tasks easier.What Is a Hybrid (Electric + Hydraulic) Jack?A hybrid jack combinesLifting strong with hydraulic force – Pressurized fluid moves bulky items upward without jitters or strain.A switch starts the pump running by itself.With most hydraulic floor jacks, you must pump again and again by hand. Instead, pressing an button starts hybrid models using an electric motor to run their pump. Power stays steady, effort drops down, lifting becomes smoother. https://standesign.ca/the-rise-of-hybrid-electric-hydraulic-jacks/ READ MORE

Nowhere is change more clear than in how lifts are made today, including modern truck jack designs. Instead of solid steel, builders often reach for lighter options like aluminum or composite mixes. Speed and simplicity start to matter more when workers need to place gear quickly. Less weight means fewer back issues later down the line. Yet here’s the catch — does lighter really mean stronger when work gets tough? Real settings demand real toughness, not just weight savings.Yes, that is correct – if engineered well and matched to proper load needs. What really matters ties into rules, purpose, and how things are used. Think about how lighter materials shape jack building, then see their impact on security. https://standesign.ca/lightweight-materials-in-jack-manufacturing-are-they-safe/ READ MORE

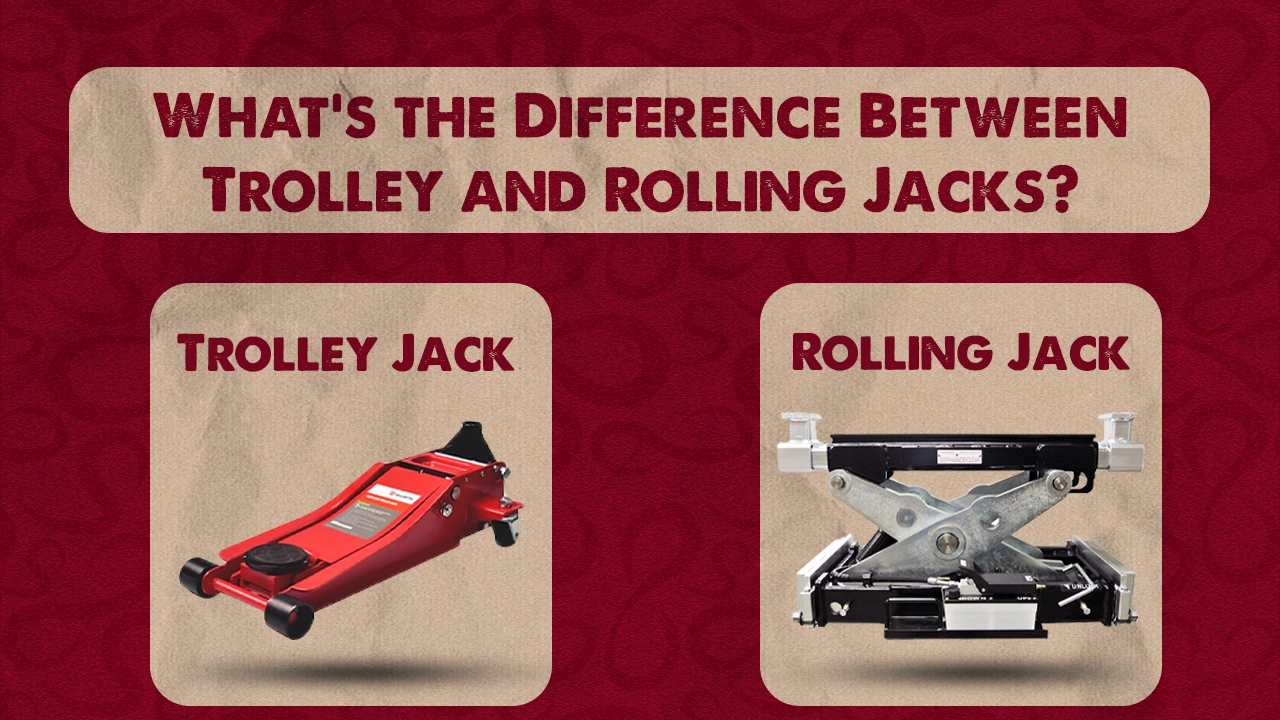

Setting up gear for a workshop or swapping out lifting tools often leaves people unsure – trolley jacks versus rolling jacks. These names might seem interchangeable since each handles vehicle lifts, yet one works entirely distinct from the other. Picking an unsuitable option tends to slow things down, create hazards, or disrupt how work flows in the bay. Figuring out what every jack does can show users where they’re really needed. That awareness often leads to better choices about tools in a workplace.What Is a Trolley Jack?A trolley jack, sometimes just called a floor jack, moves around on wheels thanks to its hydraulic setup. Built to glide beneath a car or truck, it lifts the vehicle using specific spots like the underpinning or axle area. Raising happens through turning a long handle – each squeeze of that handle shifts fluid inside, doing the work. https://standesign.ca/whats-the-difference-between-trolley-and-rolling-jacks/ READ MORE

When working on big rigs, heavy jacks aren’t just tools – they’re key partners. Lifted high, vehicles become manageable for repairs and checks. Yet even though safety checks get regular nods, something else sits in the shadows – how coverage might change after a mishap. A single misstep with raised metal can spark harm to people, harm to gear, or lawsuits piling up. That kind of pressure doesn’t vanish quietly; it reshapes cash flows fast. Every now and then, someone wonders about insurance covering heavy-duty jacks. That connection matters more than it seems. Worker safety ties directly to proper equipment handling. Equipment function often determines legal responsibility. Missteps here can slow down daily work. Worker well-being links closely to company performance.Why Insurance Matters in Vehicle Lifting OperationsHandling big machines brings built-in dangers along. Proper instruction and rules aside, surprises might happen. Money protection shows up when accidents involve staff hurt, broken tools, or harm to buildings. Insurance steps in, covering what might go wrong. https://standesign.ca/insurance-considerations-when-using-heavy-duty-jacks/ READ MORE

Not every lift fits everywhere. When work happens often, tools need room to grow beyond home setups. Weight limits matter more where vehicles change daily. Some decide based on dollars spent, ignoring what years can punish. Safety isn’t optional even if speed calls. Mistakes like these often cause machines to stop working, create unsafe conditions, or wear out too soon. Knowing what goes wrong most frequently makes it more likely to choose the correct setup from the beginning.Mistake 1: Underestimating Load Capacity RequirementsA typical error happens when choosing a floor jack just by how heavy the car is – ignoring shifts in force during use. Vehicles meant for business might hold lopsided burdens, extra items, or differ in weight across axles.Buyers should account for: https://standesign.ca/mistakes-buyers-make-when-selecting-floor-jacks-for-commercial-use/ READ MORE

With more massive and intricate trucks on the road, what lifts them must change too. Lately, air-over-hydraulic truck jacks stand out – they blend breath-powered prep with fluid-driven lift. Speed comes from air, precision from fluid, strength beyond old hand-crank designs. That mix makes climbing heights faster while still handling tight spots. Even better, new advances keep making these options safer, faster, and ready for busy truck service centers.How Air-Over-Hydraulic Systems WorkWith compressed air powering a hydraulic pump, these jacks leave some of the hard work behind. While someone still pumps the ram, a steady flow of air eases that task. Lift becomes more precise because airflow boosts force through the system.Faster lift cycles come out of this setup, operations run more quietly, technicians face lower workloads – a big help where several large machines move through busy shop floors every single day. https://standesign.ca/innovations-in-air-over-hydraulic-truck-jacks/ READ MORE

Lifting tires or changing oil takes little tech know-how, making it quick and easy on busy days. These tasks follow a clear path – no guessing needed – and people keep coming back no matter the season. Still, shops often miss big gains even when crews and cash are ready. The real holdup? Outdated lifts that stall progress instead of moving forward. Using the correct jacks cuts service hours fast, boosts safety, while boosting daily vehicle flow – this shapes how much businesses earn. https://standesign.ca/how-to-maximize-your-garages-profits-with-fast-lube-tire-service-using-the-right-jacks/ READ MORE

A wrong lift can ruin tools, harm people, or break equipment – this happens often where cars get fixed. In big truck garages or smaller workspaces for company fleets, lifting risks stay high. Mistakes around balance and weight distribution tend to sit at the core of problems. That idea about where a vehicle’s heaviest part might tip? It rarely gets discussed clearly. Most notably, it matters a lot while handling truck jacks – weight and lift height together raise the danger. Because they know how forces shift while something rises, workers and supervisors reduce mistakes, making spaces where people lift things much safer. https://standesign.ca/avoiding-lift-accidents-the-science-of-load-stability-and-center-of-gravity/

A jack sits among the top go-to items in garages, workshops, or truck shops. When it comes to working under a pickup for chores like oil changes, lifting matters. Yet when handling big rigs, relying on a truck jack can mean the difference between safe access and risk. Still, few stop to think about timing – when does even a solid jack need swapping out? Not like everyday tools, jacks never truly stop working – yet their usefulness fades over time, shaped by how often they’re used, cared for, and where. Knowing exactly when to swap yours might avoid hazards, lost minutes, or expensive fixes later. https://standesign.ca/how-often-should-you-replace-your-jack/ READ MORE

Bigger, bulkier commercial trucks roll out daily, packed with tech upgrades, yet the gear meant to handle them lags behind. What used to be simple pumps or screws has shifted toward smarter setups driven by machines learning on their own. Safety concerns now shape design decisions more than ever before. Information flows between tools once isolated from digital networks. Even how jacks are built reflects eco-friendly choices quietly gaining ground. These days, truck jacks aren’t only lifting devices – they’re evolving into smart systems built for quicker, safer service work. Looking ahead, knowing where lifting tech is trending matters – it helps fleet owners, repair shops, and mechanics keep up, meet regulations, stay sharp. https://standesign.ca/the-future-of-lifting-technology-for-commercial-trucks/ READ MORE

Most car garages rely on pneumatic jacks because they work fast, require little strength, and are simple to handle air pressure inside them makes lifting quick and smooth. In smaller repair jobs, speed matters most so compressed tools fit well when doing similar tasks again and again. Yet applying these same tools to big buses or large trucks shows clear drawbacks over time. Heavy vehicles need stronger solutions since standard jacks meant for cars often strain under thicker metal loads. That difference becomes hard to ignore once weight grows beyond what standard gear can handle.Grasping these limits matters when picking gear, boosting safety, and keeping things running under tough conditions. https://standesign.ca/limitations-of-pneumatic-jacks-in-heavy-truck-bus-maintenance/ READ MORE

A rolling jack often sits right where it’s needed – in a garage, shop, or service yard. Because they roll into place, lining up with a car without struggle, they fit smoothly into tight spaces. Lifting just one axle or the whole vehicle? That’s what these are built for. You’ll find them over service holes, humming in fast workshops, even on quiet roadside jobs. Yet quality does not always demand a high price – even on a limited income, a reliable option exists.A closer look here covers the best affordable rolling jacks that work well, hold together, and come equipped with key safeguards – no expensive extras needed. When it comes to hoisting small trucks, farm equipment, delivery vans, or larger vehicles on site, picking the right budget-friendly tool matters. https://standesign.ca/best-budget-rolling-jacks-that-dont-sacrifice-quality/ READ MORE

Picking the correct jack for a pickup truck isn’t only about making things easier – it ties into staying safe. What often confuses people is how much weight a lifting tool can handle. Not every tall lift means the job is done right. Truth is, placing a wrong‑size jack onto something might cause wobbly results – or worse.This guide explains what jack capacity ratings really mean, how they apply to pickup trucks, and how to select the right jack for safe and reliable lifting. https://standesign.ca/understanding-jack-capacity-ratings-for-pickup-trucks/ READ MORE

Lifting a semi truck is a serious task that requires proper equipment, preparation, and strict safety practices. Semi trucks weigh significantly more than passenger vehicles, and improper lifting can result in severe injuries, equipment damage, or vehicle instability. While a semi truck floor jack is commonly used in commercial maintenance environments, using one on a semi truck demands extra caution and the right approach.Every time you lift a semi using a floor jack, safety matters most. Start by blocking each wheel so the vehicle stays put during lifting. Position the jack slowly under the correct steel reinforcement near the tire area. Check every inch before raising it more than a few inches at once. Watch closely for weak spots or slipping movement. Apply steady pressure instead of rushing it upward. Keep your eyes and hands ready to respond if something shifts unexpectedly. Finish by lowering it carefully and removing those blocks when done. https://standesign.ca/how-to-safely-use-a-floor-jack-on-a-semi-truck/ READ MORE